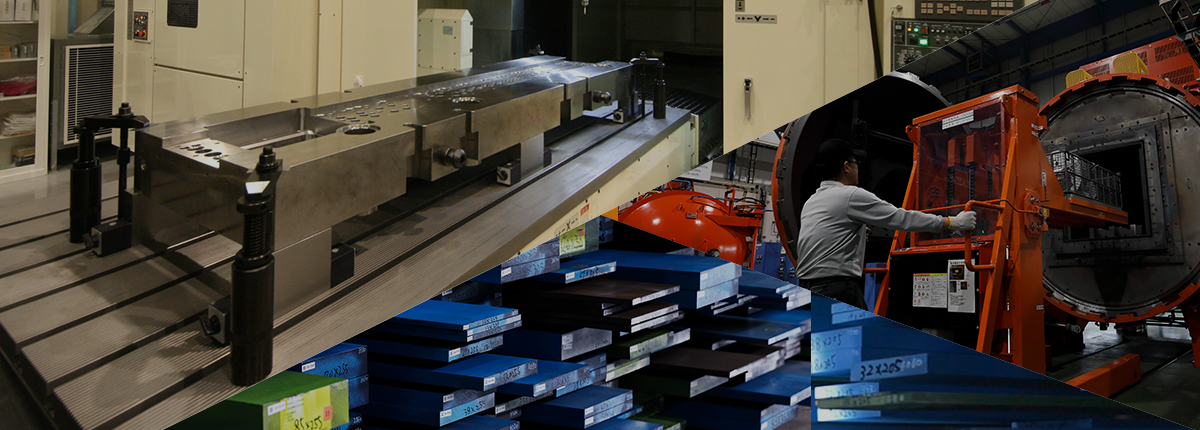

Material Supply

We have introduced the original inventory/sales/production management system for storing a wide variety of steel at all times and smoothly linking them to the next cutting process. This enables us to supply steel efficiently.

We began selling special steel in 1927. Since then, we have invested aggressively in plants and equipment such as the saw cutting machines made by the founder himself, and heat treatment furnaces. It has allowed us to respond promptly and surely in meeting our customers' needs. This style of identifying market trends and responding rapidly to them has been passed down as a legacy to the present.

A typical example can be seen in the business field handling tool steel. Most of the tool steel handled by us are used in molds for manufacturing automotive parts. We have an abundant stock of cold tool steel, hot tool steel and even steel for plastic molds, enabling us to supply steel materials that exactly meet the needs of our customers.

In addition to processes such as saw cutting, heat treatment, and finishing, the “Factory Mall” offers end-to-end manufacturing of precision-measured mold parts, a revolutionary setup that handles customers' orders in one place. We provide the best quality with the shortest processing.

We have introduced the original inventory/sales/production management system for storing a wide variety of steel at all times and smoothly linking them to the next cutting process. This enables us to supply steel efficiently.

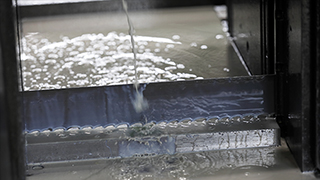

For the process of cutting steel to the required size, we have introduced the fully automated saw cutting system. The material handling equipment attached to the system packs the steel to be used and saw cutting machines, capable of operating 24 hours a day, perform the work.

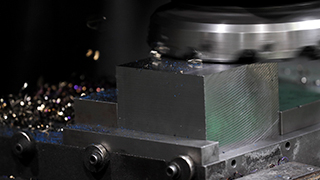

Milling is performed to remove the surface scale that causes surface unevenness. A uniform finish stabilizes quality, allowing us to estimate the machining time and achieve planned production.

Our heat treatment center features three quenching furnaces, including a large furnace installed in 2016, and nine tempering furnaces. We make full use of these two types of furnaces to adjust hardness, dimensional change, and distortion to maximize the characteristics of special steel. Which stabilizes the heat-affected layer formed during WEDM processing, thereby reducing the time-based dimensional change to 1/5 to 1/10 of the conventional level.

The Technology Development Center, where machining is performed, features a temperature/humidity-controlled room with temperature of ±0.5°C and humidity of less than 60%. We make full use of 3-axis and 5-axis machining centers to carry out finishing of more complex shapes.

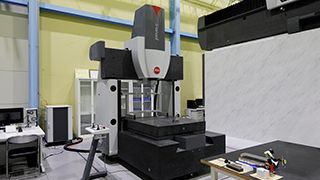

The high dimensional precision of molds is a proof of the technical capabilities employed in the preceding processes. The step of measuring proves this in numerical terms. In our accredited ISO17025 laboratory measurement environment, we utilize CMMs and non-contact measuring machine to guarantee absolute dimensions. This further increases the added value of our products.

All molds and other products made by us are delivered to our customers by Yamaichi Logistics, our own designated freight forwarding company. Our delivery system responds accurately, safely, and flexibly.

| Description | Manufacturer | Model Number | Number | Operating Range |

|---|---|---|---|---|

| JIGBORER | YASDA | YBM1224 | 1 | 2600×1500×1100 |

| JIGBORER | YASDA | YBM9150V | 1 | 1500×900×450 |

| JIGBORER | YASDA | YBM950VⅢ | 2 | 900×500×350 |

| JIGBORER | YASDA | YBM640 | 1 | 600×400×350 |

| Vertical 5-axis MC | YASDA | YMC430-5axis | 1 | 420×300×250 |

| Vertical 5-axis MC | HERMLE | C40-U(28000RPM) | 1 | 850×700×500(Φ800) |

| Vertical 5-axis MC | HERMLE | C40-U(18000RPM) | 1 | 850×700×500(Φ800) |

| Vertical 5-axis MC | YASDA | Vi40 | 1 | 900×500×450(Φ400) |

| Horizontal 5-axis MC | YASDA | H40i-2Palette | 1 | 875×740×685 |

| Vertical 3-axis MC | OKUMA | MA-VB650 | 2 | 1500×660×610 |

| Vertical 3-axis MC | OKUMA | GENOS M460 | 1 | 762×460×460 |

| wire electrical discharge machine | MITSUBISHI | MP4800 | 1 | 800×600×310 |

| wire electrical discharge machine | MAKINO | U53J | 2 | 550×370×220 |

| Grinding Machine | OKAMOTO | PSG125EX | 1 | 1200×500×570 |

| Grinding Machine | OKAMOTO | PSG158EX | 1 | 1500×800×570 |

| Grinding Machine | OKAMOTO | PSG158-CH-IQ | 1 | 1500×800×620 |

| drilling machine | Tominaga Iron Works | Radial | 1 | L1700 |

| Description | Manufacturer | Dimensions | Number | Capacity |

|---|---|---|---|---|

| Vacuum Quenching Furnace |

Chugai Ro | 800×800×1200 | 1 | 1000KG |

| Vacuum Quenching Furnace |

IHI | 600×600×900 | 2 | 500KG |

| Vacuum Tempering Furnace |

Chugai Ro | 800×800×1200 | 1 | 1000KG |

| Vacuum Tempering Furnace |

IHI | 600×600×900 | 2 | 650KG |

| Vacuum Tempering Furnace |

IHI | 400×400×600 | 2 | 200KG |

| Washing System | IHI | 600×600×900 | 1 | 600KG |

| Shot Blast | SINTOKOGIO | Φ1100×500 | 1 | 700KG |

| Honing | SINTOKOGIO | 530×530×560 | 1 | 50KG |

| Sub-Zero System |

Beltech | 550×650×750 | 1 | 350KG |

| Description | Manufacturer | Model Number | Number | Operating Range |

|---|---|---|---|---|

| Contact Type CMM |

Hexagon Metrology | Leitz PMM-C | 1 | 1200×1000×580 |

| Contact Type CMM |

Hexagon Metrology | Leitz PMM-C | 1 | 5000×4000×3000 |

| Contact Type CMM |

Hexagon Metrology | DEA Global | 1 | 2200×1200×1000 |

| Non-Contact CMM |

Hexagon Metrology | CogniTens WLS400M | 1 | 500×500 |

| Non-Contact CMM |

Hexagon Metrology | CogniTens WLS400M | 1 | 500×500 |

| Contour shape measuring machine | Tokyo Seimitsu | Contracer | 1 | 100×60 |

| Rockwell Hardness Tester |

Mitutoyo | RH-511 | 2 | |

| Shore Hardness Tester |

Mitutoyo | D Type | 2 | |

| X-Ray Constituent Analyzer |

Niton (Rigaku) | XLt898 | 1 |

We have established a business handling contract work of various processes—or even a single process—such as providing materials, milling to remove "surface scale ," and heat treatment. We can utilize our wealth of expertise in special steel and high-precision machining technologies to meet our customers' manufacturing needs.

We have also developed our business in fielding outsourced measurement using CMMs and non-contact measuring machine. The results of measurements obtained in our ISO17025-accredited environment are reflected in test reports that are accepted worldwide.

What's more, hybrid measurement using two measuring machines has contributed to the development of the new technology of reverse engineering. We can measure the dimensions of a mold with a CMM and photograph the mold with a non-contact measuring machine and convert this to data. This technology plays a major role in recreating molds for which the drawings have been lost.

PAGE TOP

PAGE TOP